Quality

We are committed towards offering optimum quality products.

OUR QUALITY POLICY

Precision. Performance. Perfection.

At Suryansh, a brand of J B S Industries India Pvt. Ltd., quality is more than a process—it is the foundation of everything we build. With 15+ years of expertise and ISO 9001:2015 certification, we are committed to delivering durable, reliable, and high-performance hydraulic gear pumps and components that meet global industry standards.

Every component undergoes advanced testing and inspection, including spectrometry, hardness testing, and CMM inspection, ensuring unmatched accuracy and long-lasting performance. From design and forging to final hydraulic bench testing, our rigorous quality control guarantees products that withstand the toughest demands of construction, agriculture, and industrial applications.

Empowering industries worldwide, Suryansh continues to set benchmarks in quality by combining cutting-edge technology with uncompromising craftsmanship.

Design & Development

Our journey begins with innovative design, where we use SolidWorks engineering tools to create precise and high-performance hydraulic solutions. Every design is validated through simulations and stress analysis to ensure accuracy, reliability, and long-term performance before production.

Casting

We use advanced casting techniques to manufacture components with excellent dimensional accuracy and consistent strength. This process ensures a strong foundation for every hydraulic part, capable of delivering reliable performance in heavy-duty applications.

Forging

Our forging process shapes components under extreme pressure, enhancing their density, durability, and fatigue resistance. This results in parts that can handle demanding environments with superior reliability and long service life.

Lab Testing (Material Testing)

Before entering production, all raw materials undergo strict lab testing, including metallurgical analysis. These checks guarantee that only materials meeting our high standards of quality and safety are used.

Lab Testing (Hardness)

Each component is subjected to hardness testing to confirm wear resistance, structural integrity, and toughness. This ensures that our products remain durable and dependable even under the most challenging operating conditions.

CNC & VMC Machining

We employ CNC and VMC machines to achieve exact tolerances and superior surface finishes. These advanced technologies allow us to deliver components with consistent precision and repeatability for maximum efficiency.

QC (Quality Control)

At every stage of production, strict quality control checks are performed to identify and eliminate defects. This ensures that each part meets our commitment to reliability and excellence.

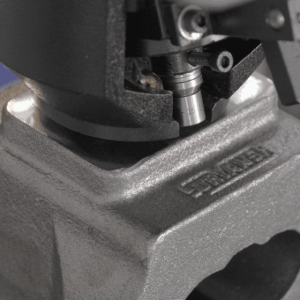

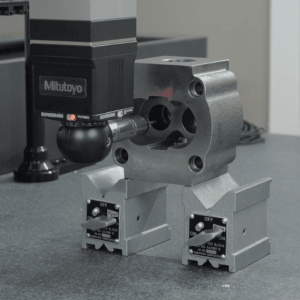

CMM Inspection

To ensure dimensional accuracy, we use a Mitutoyo Coordinate Measuring Machine (CMM) for precise inspection of components. This advanced equipment verifies critical measurements, guaranteeing that every part meets exact design specifications before moving forward in production.

Gear Processing (Hobbing & Shaving)

Our gears undergo advanced hobbing and shaving to achieve precise tooth profiles and smooth finishes. This guarantees efficient power transmission, reduced noise, and improved performance in hydraulic pumps.

Lead Profile

All gear components are inspected for accurate lead and profile using state-of-the-art measuring instruments. This ensures optimal meshing, smooth motion transmission, and noise-free performance.

Gear Grinding, OD Lapping & Face Lapping

To achieve smooth operation, we perform graining, OD lapping, and face lapping on parts. These finishing processes reduce friction, improve durability, and enhance overall efficiency.

Cleaning Raw Material

All gear components are inspected for accurate lead and profile using state-of-the-art measuring instruments. This ensures optimal meshing, smooth motion transmission, and noise-free performance.

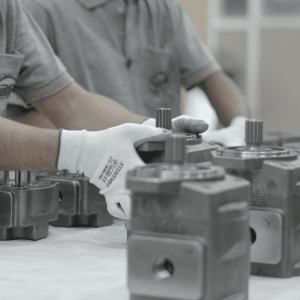

QC Assembly

Every pump and part is assembled in a controlled environment by trained technicians. Our assembly process follows standardized procedures to maintain high reliability and interchangeability.

Assembly

Before dispatch, all finished products undergo real-time simulation on our custom-built hydraulic test benches. We test for pressure, flow, leakage, and overall performance -ensuring only fully functional units reach our customers.

Hydraulic Testing Bench

Every pump and part is assembled in a controlled environment by trained technicians. Our assembly process follows standardized procedures to maintain high reliability and interchangeability.

Cutting-Edge Manufacturing

Pioneers in Design

Stringent Quality Control

Eco Friendly

Value for money product range

Dedicated Customer Support